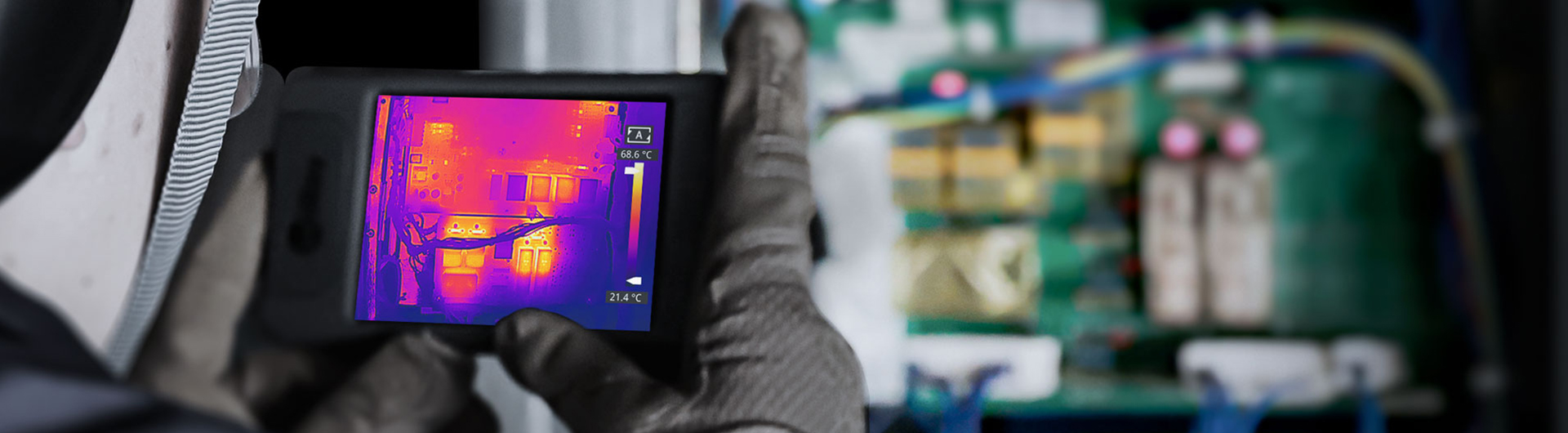

Power failure detection

The traditional power detection is only found to be faulty when the power equipment has some appearances such as burning black, scorching and explosion. When this general appearance appears, the equipment has actually been faulty for a long time, but due to the limitations of traditional detection technology However, it was not discovered in time, which led to the lag in the discovery of the fault. During the follow-up processing and maintenance, most of them needed power outage maintenance, which caused huge losses to the production enterprises and other power consumers.Due to the limitations of these traditional detection methods, the detection of power equipment is particularly difficult.Therefore, a detection tool that can detect hidden dangers early is urgently needed by the majority of electric power detection units.

With the infrared thermal imager being widely applied to the equipment inspection of the power system.

Running electrical equipment can cause overheating due to aging, looseness, poor contact, short-circuit faults, etc. Most equipment needs to go through a process from heating to failure. Hot spots can be easily found in routine infrared general testing of equipment .When electrical equipment fails during operation, the temperature will show abnormalities. This kind of temperature abnormality is difficult for human eyes to detect. Using contact detection methods will endanger human safety. However, using infrared thermal imaging cameras, you can know the abnormal temperature point only by taking pictures from a long distance.

The emergence of infrared thermal imaging cameras has added a new ray of light to the fault detection of power equipment.

Advantages of Infrared Cameras

1. Non-contact detection

Under normal circumstances, high-voltage live equipment is very dangerous and is not suitable for close contact detection. The thermal imaging camera can realize non-contact detection to ensure safe operation.

2. Detection of "no power failure"

Many live equipment need to cut off the power supply of the equipment when performing detailed inspections, which seriously affects production. The use of thermal imaging cameras for detection does not affect the operation of the equipment and does not disrupt the normal working order of the company.

3. Fast and efficient detection

Tools such as traditional temperature guns require multiple temperature measurements at a single point, and comparisons are prone to errors. The infrared thermal imager adopts multi-point simultaneous temperature measurement, which can realize "one infrared image covers the whole equipment",Taking an infrared picture is equivalent to completing all inspections of the entire equipment.

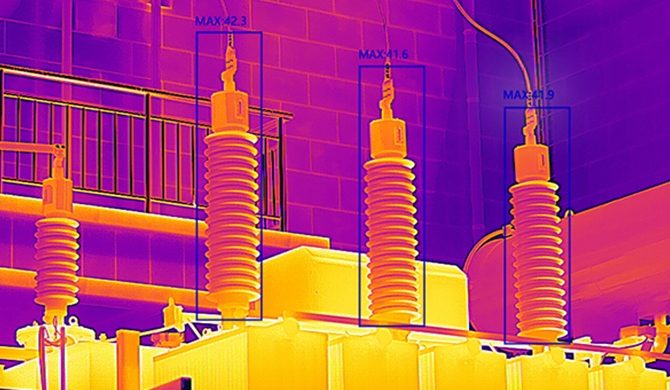

Application display

Poor contact between wire lug and wire connection

The heat map of the right phase takes the connection between the wire lug and the wire as the hottest center. Compared with the other two phases, the temperature is 1°C higher. The preliminary diagnosis is a general poor connection between the wire lug and the wire.

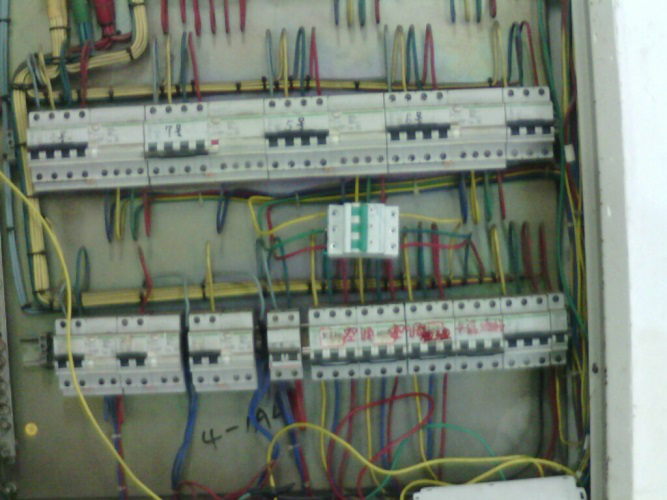

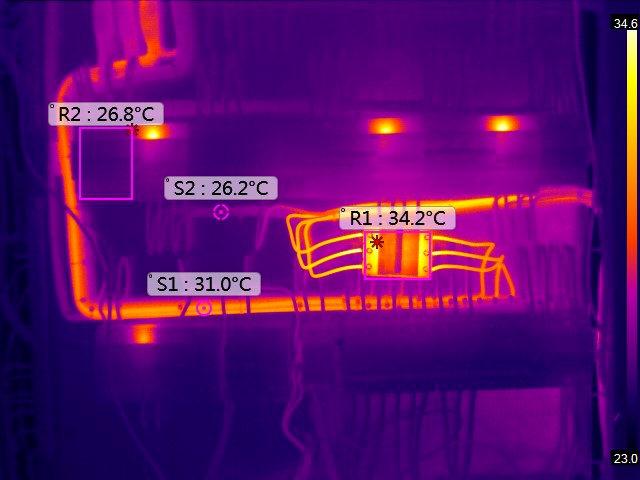

Line load of general nature is heavy

The air switch and the entire line of the cable generate heat, and the temperature of the air switch is 7°C higher than that of other air switches, and the relative temperature difference of the hot spots is calculated to be 65%. The temperature of its cable is 5°C higher than that of other cables, and the calculated relative temperature difference of hot spots is 60%. The initial diagnosis is that the line load of general nature is relatively large.