Industrial equipment application

Infrared thermal imaging cameras are widely used in the industrial industry and the field of life, and play an important, very important role. Next, let's take a look.

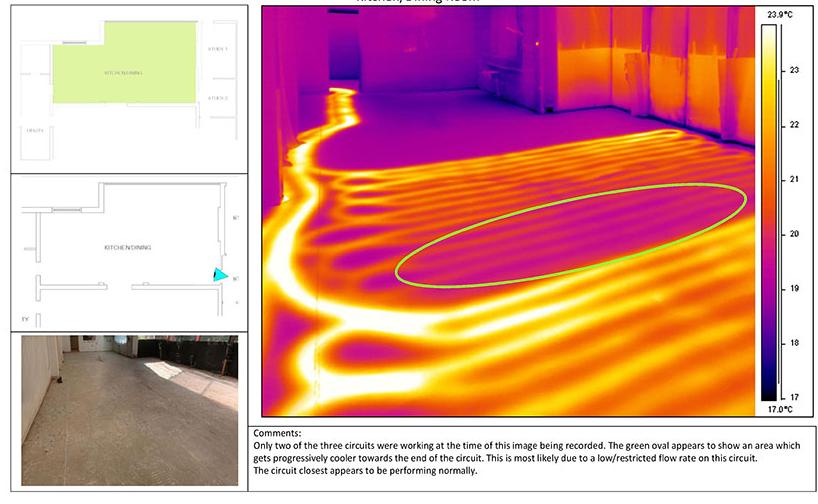

In the heating season, when the plumbing pipes in the floor are blocked, the hot water circulation is slow or even not circulating, which will cause uneven heat distribution in the room. Quickly scan the floor with an infrared thermal imager to find and locate the blockage points of the plumbing pipes; locate the plumbing The leakage point of the pipe will minimize the loss of the user. The failure of the sub-collector will also affect the heating effect of the floor heating. Using an infrared thermal imaging camera can quickly find the faulty sub-collector and assist technicians in maintenance work.

The reasons for water leakage can be summarized as follows:

1. Improper construction. When the construction party installs the floor heating system, due to improper operation or violent construction, it may cause the water heating pipe to rupture or other problems, thus burying hidden dangers for water leakage;

2. Poor pipe quality. When installing floor heating water pipes, try to choose good quality, because the floor heating system is buried under the floor, if there are problems such as water leakage, the follow-up repair project will be very troublesome;

3. Privately changed floor heating. Residents modifying the floor heating without permission can also easily cause water leakage from the plumbing pipes. The correct way is to contact the relevant professionals in time instead of acting privatel

Floor heating leaks severely damaged the walls of the house. Before using the thermal imaging camera, the usual practice in the industry is to judge whether there is any suspicion of pressure loss or leakage in the pipeline by suppressing the pressure of each sub-pipeline and changing the pressure in the pipeline over a period of time. But the biggest problem with this method is that it can only judge which floor heating coil may be leaking, but cannot accurately locate the leak point, which brings great difficulties to floor heating maintenance. If you dig the ground blindly to find water leaks, it will only cause greater losses.

If infrared thermal imaging camera is used for detection, the whole detection process and main points are mainly summarized as the following steps

1. By suppressing the sub-circuits of the floor heating, it is judged that there are leaking pipelines, and whether there is water leakage is judged by the change value of the pipeline pressure in each sub-pipeline within a time period.

2. To use an infrared thermal imaging camera, there needs to be a certain temperature difference between the floor heating temperature and the ambient temperature. The temperature that can be measured is between -20° and 400°C, and it supports multiple point temperature measurement and multiple area temperature measurement. Use a pressure test pump or a self-priming pump to inject hot water into the coil to form a temperature difference with the surrounding environment.

3. About 15-30 minutes after the hot water is injected is the golden period for detection with a thermal imager. If the time is too short, the water in the water pipe is not yet hot, and the temperature difference is not obvious; if the time is too long, the ground has been fully heated, and the temperature difference is not obvious. Plug your thermal imaging camera into your smartphone or tablet and start observing. The test starts about 15-30 minutes after the hot water is injected. If the time is too long, the ground has been fully heated, and the temperature difference is not obvious.

4. The detection found that the temperature in the picture is higher than other areas. Focusing on the changes in this high-temperature area, it was found that the area of the high-temperature area gradually expanded, and at the same time, the pressure of the pipeline was gradually reduced, which is a typical water leakage phenomenon. So far, the water leakage point of the coil has been clearly locked. Focus on observing the high temperature area to determine the leak point.

After the water leakage point is determined, for the owner, the maintenance area is reduced and the economic loss is reduced. For the maintenance engineer, it is possible to accurately check and repair the problem point, which reduces the workload and improves the work efficiency.

Automobile Safety Inspection

Infrared thermal imaging cameras have been widely used in the automotive field and have a long history. They can not only be used in the daily maintenance and inspection of automobiles, but also in the inspection of electrical equipment in automobile production plants. They can also play an important role in the development and production of automobiles. XIN infrared thermal imaging camera and supporting system can quickly, effectively, clearly and accurately detect the faults in the car design and structure, and accurately find the fault point.

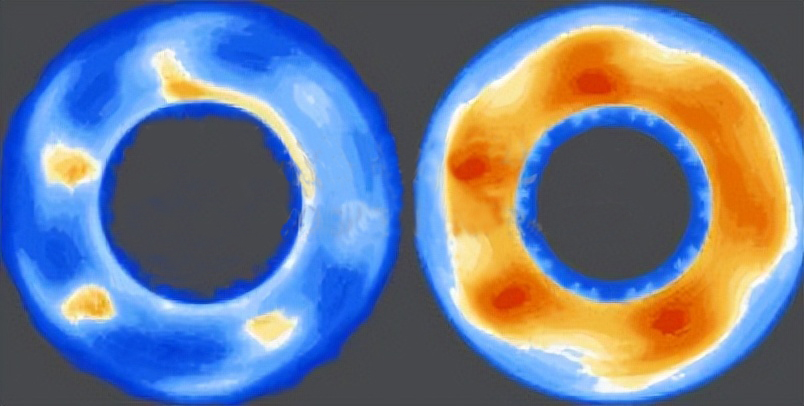

1. New energy battery heating detection

As new energy vehicles become more and more popular, the safety and performance of new energy vehicle batteries are getting more and more attention. During the experiment and development of new energy batteries, some test equipment and interior will have heat. It will affect the stable operation of the equipment for a long time, and may seriously endanger the life safety of the staff. In order to ensure the safe and stable operation of test equipment and equipment, infrared thermal imaging cameras can be used for online monitoring.

2. Automobile engine fault diagnosis

The engine is the core component of the car. If the temperature is too high or too low, it will affect the normal operation of the engine, increase fuel consumption, increase the wear and tear of the parts and reduce the service life of the engine. Some subtle defects of the engine are not easy to find through vibration and noise tests, but the use of infrared thermal imaging cameras can reflect subtle structural defects as subtle temperature differences, so that diagnostic effects that cannot be achieved by other methods can be achieved.

Observing the temperature of the exhaust pipe with an infrared camera can provide an indirect assessment of the operation of the engine system. If the temperature of the exhaust pipe is too high, it reflects the insufficient combustion of fuel. If the temperature distribution of the pipeline is uneven, it reflects the structural defects of the pipeline itself. Compared with the current vibration, pressure, energy consumption, exhaust and other corresponding methods, the use of infrared thermal imaging technology has the advantages of non-contact, non-interference, non-destructive, accurate and clear, saving manpower and material resources, and the temperature characteristic direction corresponding to the fault Clear, can accurately find the point of failure.

4. Automobile brake pad detection

The choice of brake pad friction material largely determines the braking performance of the brake pad. Temperature is an important factor affecting the performance of brake pads, so temperature detection is very important in the research of brake pad materials. When the temperature of the brake pad is too high, the working efficiency will be reduced. If the friction material of the brake pad is too soft, the temperature of the brake pad will rise sharply after continuous braking, and the braking force will drop significantly. On the contrary, if the friction material is too hard and the temperature change tends to be slow, it will accelerate the wear of the brake pads and discs, and the brake pads may crack or fall off during emergency braking, eventually leading to brake failure.

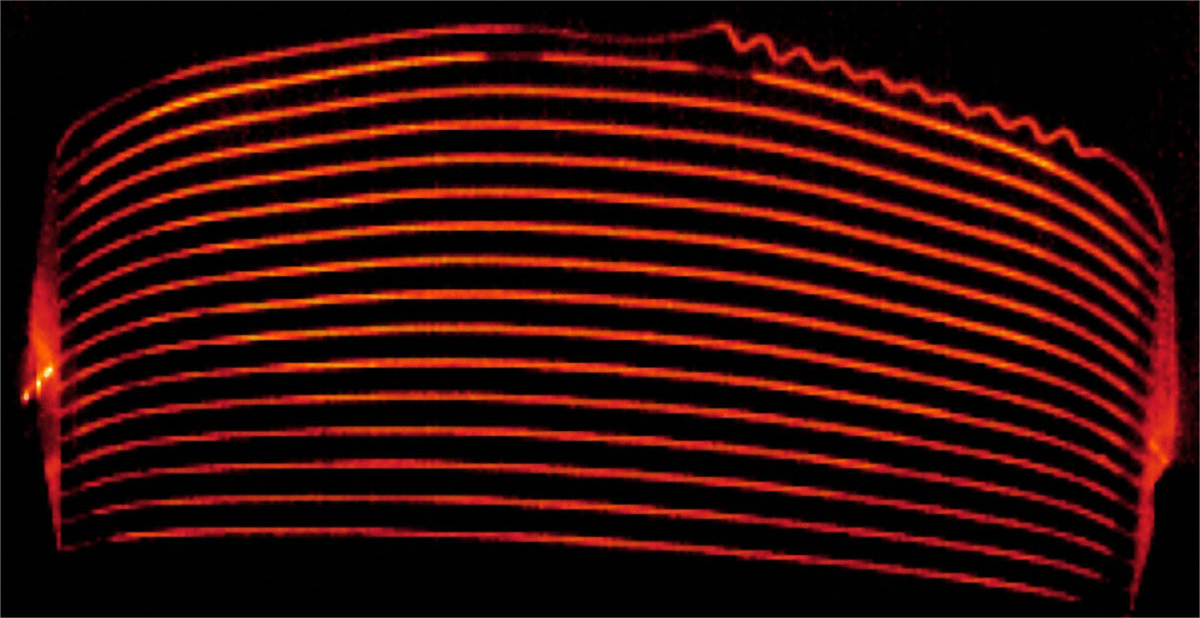

3. Rear windshield heating wire detection

The use of infrared thermal imaging cameras can help the rear windshield heating system of the car to be safer and more effective. The rear windshield heating system of the car is mainly the heat generated by the electric current passing through the embedded resistance heating wire inside the glass, which is evenly distributed on the glass. Automobile development engineers use infrared heat The imager quickly and conveniently obtains the thermal image of the rear windshield during the heating process of the resistance wire, analyzes the temperature field distribution of the resistance wire, and avoids uneven distribution of resistance wire or abnormal resistance, which is beneficial to avoid glass damage caused by local heating of the glass or excessive heating even the risk of bursting.

5. Body air tightness test

The quality of the car's air-conditioning system is very important to the car experience, and the overall airtightness of the car body will directly affect the working efficiency of the air-conditioning system. When testing the air tightness of a car, turn on the air-conditioning system in the car and run it for a period of time, and then use an infrared thermal imager to take a heat map of the whole car. The temperature at the location is not the same as the temperature of the external environment, so that it can provide accurate analysis and evaluation of the overall airtightness of the vehicle body.

6. Detection of automobile exhaust pipe

Excessive exhaust pipe temperature can reflect incomplete combustion, thus providing an indirect assessment of the working condition of the engine system. If the temperature distribution of the pipeline is uneven, it can reflect that the pipeline itself has structural defects. In addition, the bearing system of the automobile chassis, electrical equipment, and the comfort of the body can all be detected and diagnosed by thermal imaging cameras.